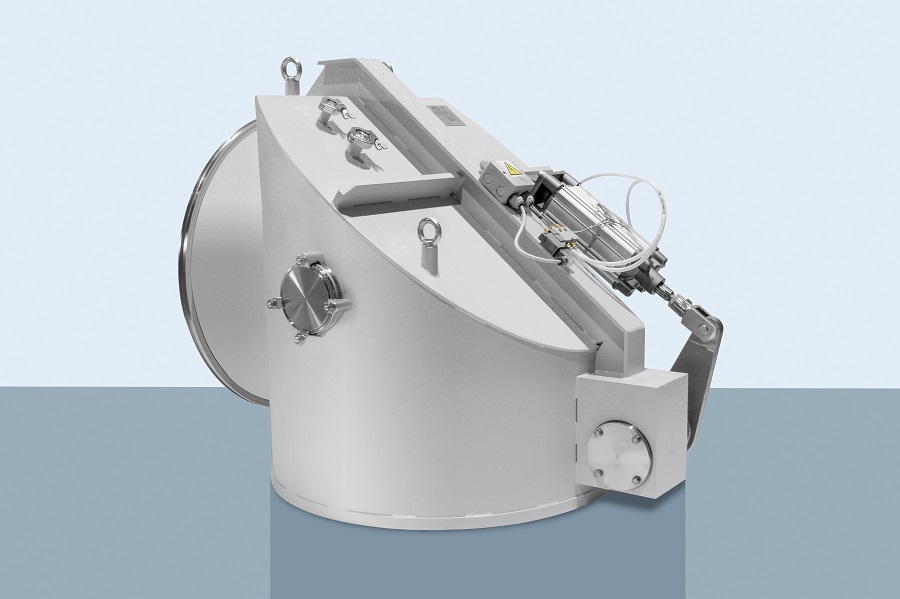

The HV angle valves are mainly used as the main valve between vacuum chamber and high vacuum pump. The valves ensure an optimal conductance in the opening position and can be upgraded to a 3-Position valve. The valves can be made x-ray safe for applications at high energy e-beam systems. The nominal widths are DN 400, DN 500, DN 630, DN 800, DN 1000.

Technical specifications:

- Housing made of stainless steel or mild steel, painted

- Stainless steel valve plate

- Connections for bypass line and sensors

Options:

- Special flange connections

- Size and position of the connections for bypass line and measuring technology

- 3-Position-valve

- X-ray protection

Example: HV-angle valve DN 630

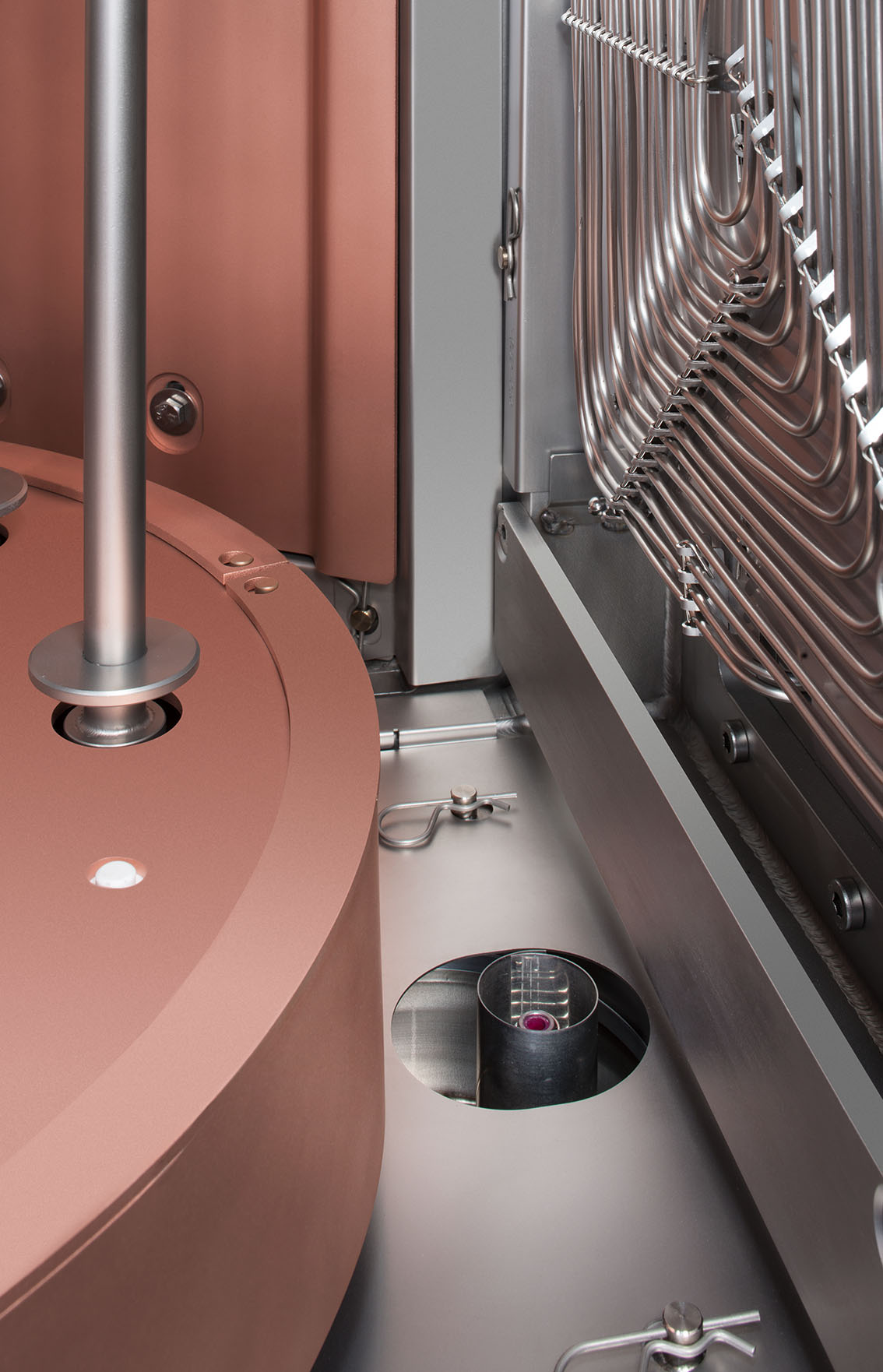

VTD's source "AS-65-M" is a magnetically steered metal arc evaporator for 65 mm diameter targets. It is applicable for metallization and hard coating.

All common, preferably highly melting metals (Ti, Cr; Zr, Nb etc.) can be evaporated. Nitrides, carbides or carbonitrides can be generated by additional reactive gas inlet.

Features:

- Setting the magnetic field without venting the system

- Reduced droplet number through steered arc

- Electric arc ignition without mechanical trigger

- Optionally with source shutter

- Customized Arc power supply available

The hollow cathode plasma source generates a high-currrent low-voltage gas discharge. The hollow cathode effect caused by pendulum electons and thermal electron emission leads to a high plasma density inside the hollow cathode tube and in the expanding plasma volume.

Applications

- Ion etching and activation of the substrate surface

- Ion/plasma-assisted evaporation

- Thermal treatment and heating of substrates